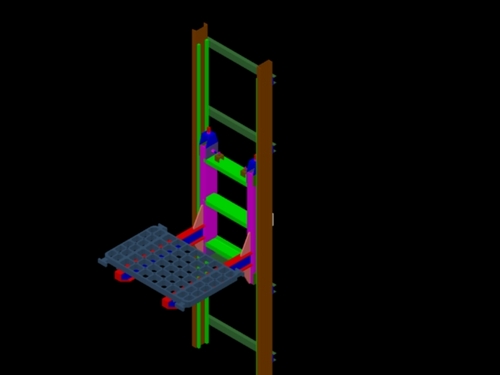

Fork Assembly

Price 500000-10000000 INR/ Set

Fork Assembly Specification

- Color

- Metallic silver

- Product Type

- Fork Assembly

- Material

- High-grade steel

- Application

- Mining, various industries

- Condition

- New

- Power

- Manual/Mechanical

- Use

- Industrial lifting

- Capacity

- Heavy-duty load bearing

- Design

- Robust, precision-engineered

- Weight

- 18 kg (may vary by model)

- Maintenance

- Low, periodic lubrication recommended

- Length

- Approx. 1 meter (customizable)

- Width

- Approx. 150 mm fork width

- Mount Type

- Bolt-on or clamp style

- Thickness

- 30 mm (fork section)

- Compatibility

- Standard industrial machinery

- Temperature Resistance

- -20°C to 80°C

- Surface Finish

- Anti-corrosive coating

Fork Assembly Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 2 Sets Per Month

- Delivery Time

- 2 Months

- Packaging Details

- Standard Export Packaging in Wooden Case

- Main Domestic Market

- All India

- Certifications

- ISO 9001: 2008

About Fork Assembly

Fork Assembly

Our firm has the support of our experienced manpower, which assists us in manufacturing and exporting Fork Assembly. This product is engineered by making use of superlative quality material and sophisticated techniques. To fulfill the application requirements of our wide and reputed client base, we offer these products in distinguished sizes, efficiencies and specifications. Front Fork Assembly is idyllic to be used in industries for lifting applications.

Features:

- High sturdiness

- Corrosion resistant

- Optimum durability

Precision Engineering for Industrial Reliability

Designed to meet the demands of standard industrial machinery, this fork assembly features meticulous manufacturing standards for consistent performance. Its robust build guarantees operational stability and longevity across varied environments, particularly in mining and heavy-duty industrial applications.

Superior Material and Surface Protection

Manufactured from premium-grade steel, each fork assembly is treated with an anti-corrosive coating. This surface finish provides essential resistance against harsh elements, protecting against rust and extending the functional life of the component even under frequent use.

Flexible Mounting and Customization Options

Choose either bolt-on or clamp-style mounts for quick installation on a range of equipment. Customizable dimensions ensure compatibility with diverse machinery setups, allowing seamless integration and optimal lifting efficiency in various sectors.

FAQs of Fork Assembly:

Q: How is the fork assembly installed onto industrial machinery?

A: The fork assembly can be easily mounted using either a bolt-on or clamp style, depending on your equipments requirements. This flexible design ensures secure attachment and compatibility with most standard industrial machines.Q: What are the maintenance requirements for this fork assembly?

A: Maintenance is low and primarily involves periodic lubrication of the moving fork sections. The anti-corrosive surface finish minimizes the need for frequent servicing, making it suitable for continuous use in challenging industrial settings.Q: When should I consider customizing the fork assembly dimensions?

A: Customization is recommended when your machinery has unique requirements beyond the standard 1 meter length, 150 mm width, or 30 mm thickness. Our service providers in India can tailor the fork assembly to fit specific applications or load capacities.Q: Where can this robust fork assembly be used?

A: The fork assembly is designed for versatile use in mining, manufacturing, logistics, and various industrial sectors that require reliable lifting and handling solutions. It integrates effectively with standard industrial platforms in these environments.Q: What are the benefits of the anti-corrosive coating on this fork assembly?

A: The anti-corrosive coating protects the high-grade steel from rust, extending the products operational life even under exposure to moisture, chemicals, or extreme temperatures. This ensures continued safety, reduced maintenance, and long-term reliability.Q: Is the fork assembly suitable for heavy-duty load bearing?

A: Yes, this fork assembly is precision-engineered to handle heavy-duty loads, making it ideal for demanding industrial tasks. Its robust design and quality materials ensure maximum strength and stability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Foundry Equipment Category

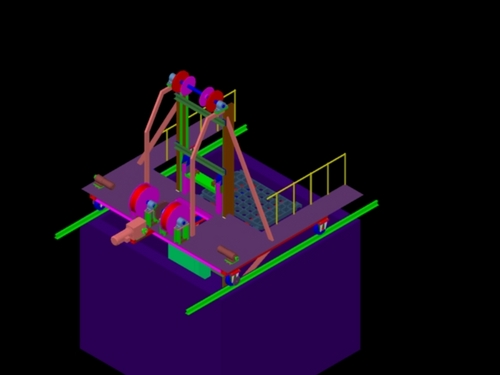

Ladle Pre Heater

Price 500000-10000000 INR / Set

Minimum Order Quantity : 1 Set

Application : Mining, various industries

Color : Blue

Product Type : Ladle Pre Heater

Use : Preheating ladles

Fork Arm

Price 500000-10000000 INR / Set

Minimum Order Quantity : 1 Set

Application : Mining, various industries

Color : Black

Product Type : Fork Arm

Use : Lifting and material handling

Sand Drier System

Price 500000-10000000 INR / Set

Minimum Order Quantity : 1 Set

Application : Mining, various industries

Color : Customized

Product Type : Sand Dryer

Use : Various Industries

ISO 9001: 2008 Certified

|

VMH THERMAL TECH ENGINEERING PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry